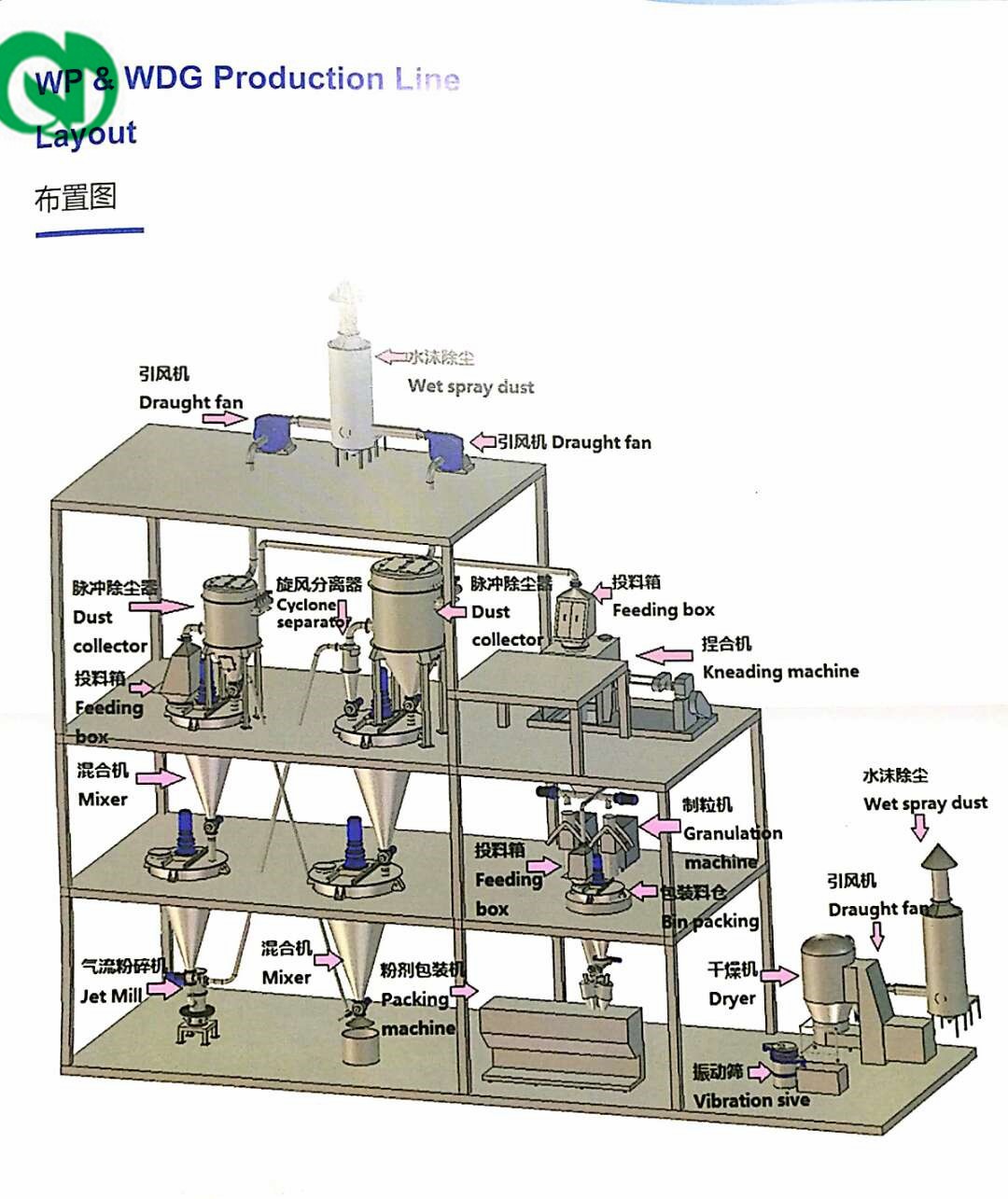

Nidaamka WP-WDG-Codso Goobta Agrochemical

Qaybta WP

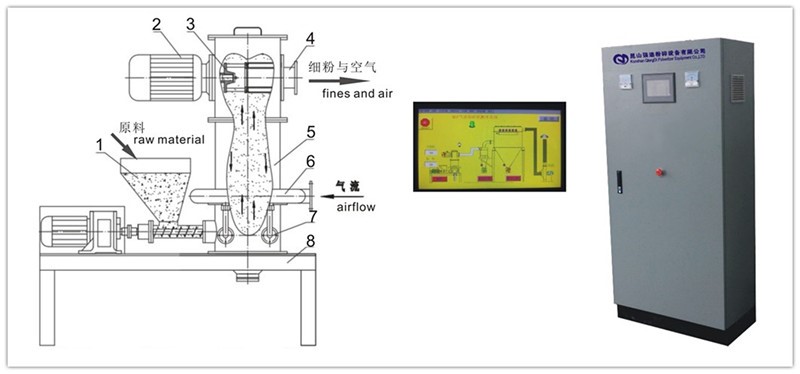

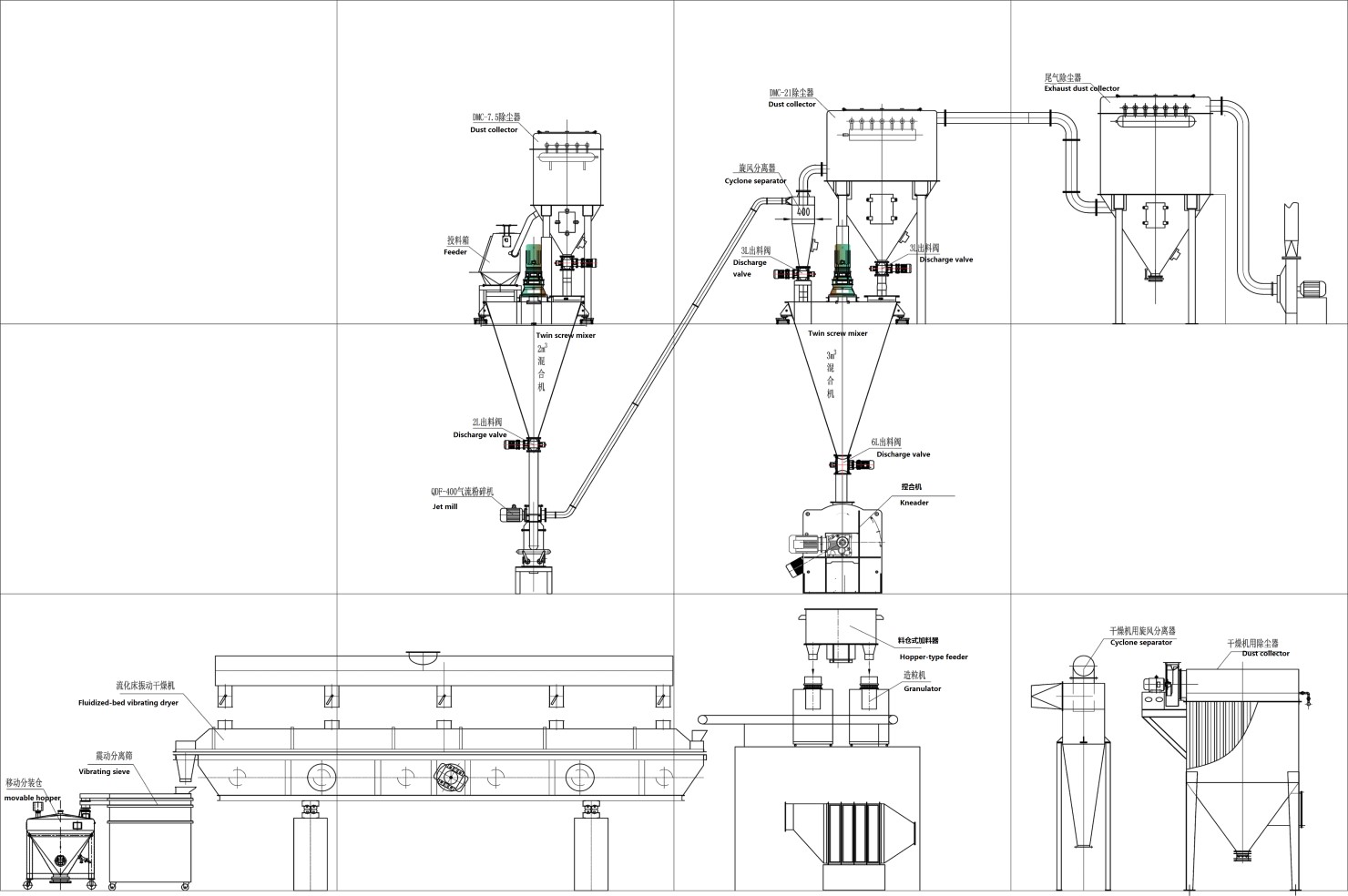

Marka hore, alaabta ceeriin waxay ka quudisaa quudiyaha - wareejinta walxaha ilaa 3 mitir ee ugu horreeya3Mixer for premixing, iyo boodhka ururiyaha ururin doonaa boodhka inta lagu guda jiro habka quudinta, ka dibna walxo isku qasan galaan QDF-600 jet mishiinka wax lagu shiida, size qayb wax soo saarka lagu hagaajin karaa by hagaajinta xawaaraha kala duwan ee wareeg ah ee giraangiraha classifier,. Wax-shiidka ka dib, alaabtu waxay u wareejin doontaa duufaanta iyo boodhka ururiyaha sare ee 4m ee hore3qase iyada oo loo marayo xoogga centripetal ee marawaxada qabyada ah, ka dibna u gudbi 4m labaad3qaseeyaha isku dhafka kahor xirmada ama u wareejinta nidaamka WDG.

Nidaamka WP waa isku dhafka ugu fiican ee tiknoolajiyada jet-ka, tignoolajiyada isku dhafka ah iyo tignoolajiyada xakamaynta caqliga leh. taas oo ah badeecad ku qanacsan sunta cayayaanka si isku dhafan oo isku dhafan, Dhanka kale, waxay la kulmeysaa codsi deegaan oo aan boodh lahayn inta lagu jiro habka oo dhan.

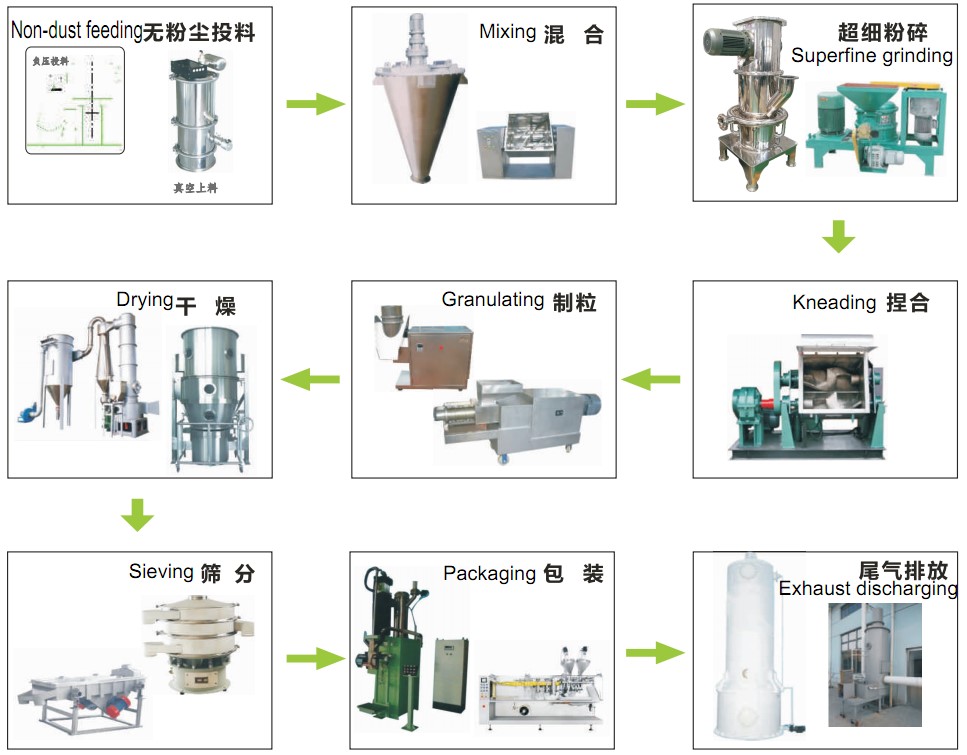

WDG (granule biyaha la firdhi karo) sidoo kale loo yaqaan budada qoyan ee qalalan wakiilka ama nooca hadhuudhka, alaabta ceeriin ee budada qoyan (WP) sameeyay by granulation hal mar biyaha, si degdeg ah u kala firdhi karaa oo kala firdhiyey, foomka diyaarinta granular sare hakiyey nidaamka kala firdhiso adag.

Granulation waa udub dhexaadka habka oo dhan. Granulator waa furaha si loo hubiyo in sunta cayayaanka granulated iyo habka qalajinta la isku hagaajiyay, taas oo ku saleysan sifooyinka sunta cayayaanka, xogta tijaabada ah iyo tusaalooyinka codsiga injineernimada, doorashada granulator extrusion rogrogmi ama granulator fur furka mataanaha ah. granulator (Habka granulation sariirta dareere ah iyo geeddi-socodka granulation extrusion waa ka duwan yahay) Shuruudda qoyaanka qoyaanka ee granulation waa qiyaastii 8-18% . Iyada oo ku saleysan sifooyinka badeecada iyo hababka wax soo saarka, si loo go'aamiyo naqshadeynta habka inta badan waxay ka kooban tahay: cajiin, granulation, qalajinta, baaritaanka, baakadaha, nidaamyada hawada kulul, nidaamka ka saarista boodhka.

Marka hore, alaabta ceeriin waxaa loo rari doonaa 1000L Buffer, ka dibna itto ZGH-1000 mashiinka qaso toosan by Vacuum ZKS-6 waayo, qaso qoyan ka dibna loo qaado XL-450 extrude granulator (3pcs) iyada oo qaybiyaha 500L ee granule qoyan, ka dibna si QZL-1300. Qalajiyaha sariirta dareeraha leh ka dibna ZS-1800 shaandhada gariirka centrifugal ee shaandho si aad u hesho granul cabbirka loo baahan yahay.

Qalajiyaha sariirta dareeraha gariiraya ee budada kiimikada ah

Qalajiyaha sariirta dareeraha gariiraya ee budada kiimikada ah

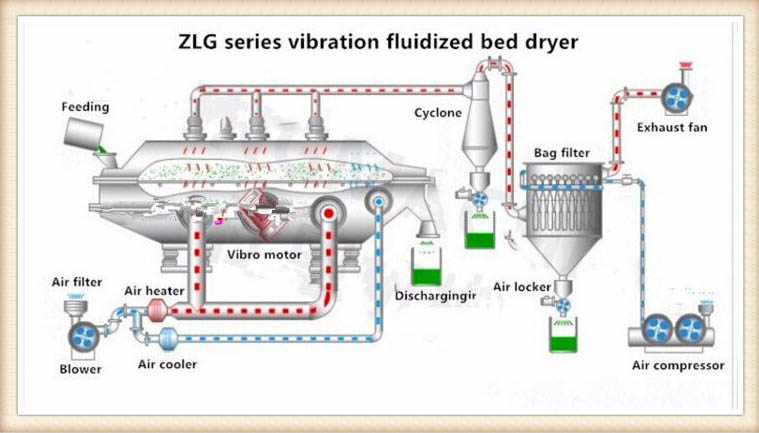

Mabda'a Shaqada

Sariirta dareeraha gariirku waa tignoolajiyad cusub oo lagu sameeyay sariirta dareeraha dareeraha ah. Gariir makaanikada ayaa lagu daraa sariirta dareeraha ah. Qaybaha walxaha qoyan waxay galaan qulqulka hawada waxayna sameeyaan sariir dareere ah. Maaddada ayaa laga saaray xoog xiiso leh awgeed. Gariirada saxan qaybinta hawadu waxay kicisaa dareeraha walxaha walxaha iyo dhaqdhaqaaqa walxaha sariirta dareeraha ah. Maaddada dareeraha ah waxay la xiriirtaa hawada kulul isla mar ahaantaana waxay qaadataa kulayl iyo wareejin ballaaran. Badeecada engegan ayaa lagu daadiyaa iyada oo loo sii marayo dekedda laga sii daayo.

Astaamaha

1. Waxay isticmaashaa tignoolajiyada horumarsan ee vibrofluidization, waxyeelada walxaha engegan ee dusha sare ee walxaha waa yar yahay.

2. Dhaqdhaqaaq joogto ah, la qabsi fiican.

3. Gariirku wuxuu keenaa dareere, heerka socodka hawada qalajinta ayaa la yareeyaa, qaybo yar ayaa la isku dhejiyay.

4. Waqtiga deggenaanshaha walxaha waa mid joogto ah, tayada alaabadu waa lebis.

5. Waxaa loo isticmaalaa qalajinta walxaha xasaasiga ah ee kulaylka waqti gaaban, sida, biyaha dusha sare

qalajinta CUSO4 · 5H2O ka kooban biyo crystal ah, MgSO4 · 7H2O.

Baaxadda lagu dabaqi karo

Waxaa loo isticmaali karaa in geeddi-socodka qalalan ama qaboojinta, lagu dabaqi karo in ay qayb weyn ama qayb iyo ma fudud socodka aan joogto ahayn ee alaabta, ama sababta oo ah in la sameeyo qayb ka yar dalbanaya iyo sii dhamaystiran xawaaraha fluidization ee alaabta iyo fududahay in bond, xasaasi u ah heerkulka qalajinta oo ka kooban alaabta gesso alaabta dusha biyaha ka saarida.

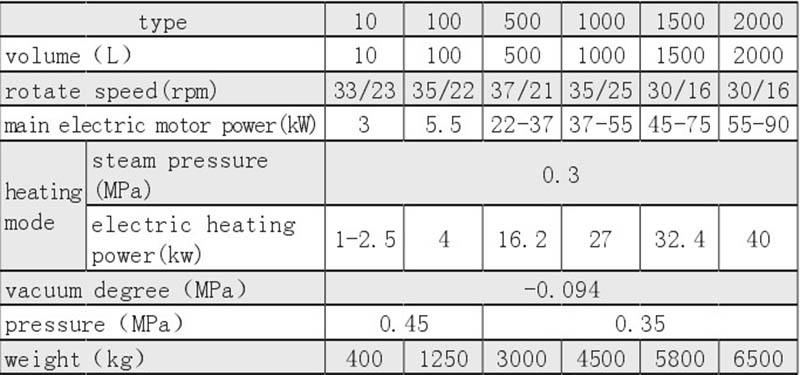

Halbeegga farsamada

| Qaabka | Aagga sariirta dareeraha leh (M2) | Heerkulka hawada gudaha (oC) | Heerkulka hawada ee dibadda (oC) | Awoodda uumiga biyaha (kg) | Matoorka | |

| Qaabka | Kw | |||||

| ZLG3×0.30 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.30 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

| ZLG4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

| ZLG4.5×0.60 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

| ZLG6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5×2 |

| ZLG6×0.60 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5×2 |

| ZLG6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2×2 |

| ZLG6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2×2 |

| ZLG7.5×0.60 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2×2 |

| ZLG7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0×2 |

| ZLG7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51-6 | 3.0×2 |

| ZLG7.5×1.2 | 9 | 70-140 | 40-70 | 200-260 | ZDS51-6 | 3.0×2 |

Guud ahaan codsiyada

Mashiinkaani wuxuu qaataa hal lammaane oo wareeg ah oo wareeg ah si uu u shiido qaab qoyan oo ah granule qaab-dhismeedka birta ah ee dhululubo shaandheeyo birta ah kaas oo lagu bixiyo pelletize habka soo socda.

Waxay ka baaraandegi kartaa alaabta qoyan waxayna heli kartaa cabbir kala duwan iyadoo loo eegayo walxaha iyo shuruudaha.

MABADA SHAQADA:

Awoodda mootada waxaa lagu kala qaadaa suunka-geeska saddex-xagalka ah ee sanduuqa gear-ka ee goobta martida loo yahay, waxaana loo qaybiyaa awooda qaybaha gudbinta ee sanduuqa marsho. Ku dar walxo ceeriin ah hopper quudinta, ka riix xagga sare.

Ka dib marka la isku daro, walxuhu waxa ay ku soo qulqulayaan weelka quudinta waxaana lagu qasbay in dibadda loo saaro daab gaar ah. Marka maaddadu ay ku soo ururto farqiga u dhexeeya daab iyo shabagga shaaha, mindida gooyntu waxay gooyn doontaa cabbir midaysan.

Qiyaasta Farsamada:

| Soo baxay | 150-250kg/saacaddii (qaab jajaban), 50-100kg/saacaddii (qaabka granule) |

| Cabbirka granules | 0.5-2mm |

| Cadaadiska ugu badan | 294Kn (30T) |

| Cadaadiska dhinaca xiritaanka | 9.8Kn |

| Matoorka quudinta | 2.2Kw |

| Matoorka Granulating | 2.2Kw |

| Matoorka cadaadiska | 7.5Kw |

| Xawaaraha isbiirsaday ee quudinta | 6-33 la hagaajin karo |

| Cadaadiska xawaaraha giraangiraha | 4-25 la hagaajin karo |

| Cabbirka giraangiraha cufan | 240X100mm |

| Miisaanka (qiyaastii) | 2000Kg |

| Cabbirka cutubka ugu muhiimsan | 1600X1000X2300mm |

| Xakamaynta cabbirka golaha | 600X400X1300mm |

Isticmaalka

Mashiinku wuxuu inta badan ku habboon yahay warshadaha dawooyinka, warshadaha cuntada, warshadaha cabitaannada adag iyo wixii la mid ah, Waxay ka dhigi kartaa walxaha cayriin ee la walaaqay inay noqdaan qanule loo baahan yahay. Gaar ahaan, waxay ku habboon tahay alaabta ceeriin ee leh dhejis dhejis ah.

Astaamaha:

Dhammaan qaybaha lala xiriiro alaabta ceeriin ee mashiinkaan waxay ka samaysan yihiin bir aan fiicneyn. Muuqaalkeedu waa qurux. Soo dayntiisu si toos ah ayey u socotaa.Sidaas darteed waxay ka fogaan kartaa xaaladaha dhaawacan ee ay sababeen buug-gacmeedka. Way ku habboon tahay wax soo saarka khadka sidoo kale.

Farsamada ugu weyn ee patameters

| Cabbirka mindida wax lagu shiidayo (mm) | 300 | 400 |

| Dhexroorka granule (mm) | Φ2 ~ 2.2 (Waxay noqon kartaa mid waafaqsan shuruudaha macaamiisha) | Φ1.2 ~ 3 (Waxay noqon kartaa mid waafaqsan shuruudaha macaamiisha) |

| Guud ahaan cabbirrada (mm) | 700×540×1300 | 880×640×1300 |

| Awoodda matoorka (kw) | 3 | 4 |

| Miisaanka (kg) | 350 | 400 |

| Awoodda wax-soo-saarka (kg/saacaddii) | 100-200 | 140 ~ 400 |

Mabda'a

Isku dhafka nooca LGH wuxuu ka kooban yahay seebabka wax soo diri ee hoose iyo seebab xawli sare leh, seebabka hoose waxay si joogto ah u soo diraan walxaha xagga sare ee darbiga weelka.

Seebabka xawliga sare leh ayaa jejebiya walxaha si buuxda uga dhigaya walxaha wareegga sida vortex-ka, si ay u dhammeeyaan isku dhafka isku midka ah waqti gaaban gudaheed.

Astaamaha qalabka

Mashiinka isku dhafka xawaaraha sare ee nooca LGH waa nooca cusub ee wax-ku-oolnimada sare ee warshadeena, kaas oo soo ururiyay farsamada horumarsan ee gudaha iyo dibadda. Tilmaamaha ugu muhiimsan waa sida soo socota:

1. Dhuxusha walxaha hoose waxay si joogto ah ugu soo diraan walxaha sare iyada oo loo marayo xoogga centrifugal. Maaddada ugu sarreysana waxay hoos ugu dhacdaa xagga hoose ee xarunta, si ay maaddadu u wareegto wareegga wareegga.

2. Dheebka-xawaaraha sareeyo ayaa jejebiya alaabtii ugu badnayd ee soo dirta seebabka hoose.

3. Maaddadu waxay isku dari kartaa si isku mid ah waqti gaaban sababtoo ah labada seeradood ee kacaanka xawaaraha sare leh. Xawaaraha isku dhafka ah iyo isku-dhafka ayaa ah midka ugu fiican dhammaan noocyada mashiinka isku-dhafka ee suuqa gudaha. Labbiska waa 100% isku dhafan.

4.Bilow furaha dareeraha ah, xawaaruhu waa mid aad u dhakhso badan, mishiinkana waa sahlan tahay in la nadiifiyo.

5.Qaybaha xiriirka mashiinka waxaa lagu sameeyay birta aan nadiifka ahayn, inta lagu jiro habka isku-dhafka, maaddadu ma isbeddeli doonto, metamorphic iyo lumay.

6.Mashiinku wuxuu ku habboon yahay qalab qallalan oo qoyan oo kala duwan si loo isku daro, gaar ahaan ku habboon isku dhafka nuxurka digaaga, daawada kala diri, cabitaanka kala diri iyo wixii la mid ah.

Waxa kale oo loo yaqaan sifter vibro rotary, shaandheeyo gariir. Waxay sifeyn kartaa dareeraha sida biyaha wasakhda ah iyo saliidda wasakhda iwm, ka saarta wasakhda ku jirta walxaha, sida budada caanaha, bariiska, galleyda iwm. Kala saar / u dhig budada isku qasan cabbir kala duwan oo aad u baahan tahay.

Sharaxaada

Dhuxusha Rotary/Dhuxusha ultrasonic gariiriyaha shaashadda mishiinka ayaa la qaatay farsamooyin horumarsan oo qalab baadhiseed oo casri ah. Waxay ka kooban tahay soo saaraha ultrasonic iyo shaashadda gariirta. Waa horumar muhim ah oo laga gaaray hufnaanta baarista. Mashiinkan shaandhaynta ayaa qabata kontoroolka ultrasonic gariiraya ee garaadka sare leh wuxuuna xaliyay dhibaatooyin badan oo ay sababeen hal jeer, si dhab ah u garanaya isku darka macquulka ah ee shaqada ultrasonic iyo shaandhada gariirka.

Shaqooyin badan sida soo socota:

1. Kala saarid

Nooca lakabka badan ayaa baari kara oo kala saari kara shan kooxood oo qaybo kala duwan isku mar ah. Waxay ku habboon tahay alaabta qallalan.

2. Shaandhaynta

Isku darka adag iyo dareeraha ayaa si wax ku ool ah loo kala saari karaa hal ama nooc lakabyo badan oo kala duwan oo kala duwan.

3. Ka saar waxyaalaha wasakhda ah

Cutubku wuxuu si dhakhso ah u kala saari karaa dhawr xajmi ama ka yar oo qaybo ka mid ah tirada agabka

Nadiifinta nidaamka waxaan u isticmaalnaa qalabka ultrasonice ee Rotary dhuxusha / dhuxusha ultrasonic gariiraya shaashadda mashiinka shaandheynta

Qaybaha tafaariiqda

Kneader waa qalab ku habboon in la cajiiyo, lagu qaso walxaha polymerize oo leh viscosity sare iyo balaastiig elasto ah. Qayb kasta oo cajiin ah ayaa leh laba xabbadood oo sigma ah gudaha qolka isku-dhafka w nooca. Waxaa si weyn loo isticmaalaa in lagu cajiiyo, la isku qaso, la burburiyo, la firdhiyo oo dib loo-polymerize koollada sare ee viscosity ama elastoplastic, taas oo aan lagu farsamayn karin qasayaasha guud ee budada ah iyo kuwa dareeraha ah. Waxaa loo isticmaali karaa warshadaha looga baahan yahay cajiin cufnaanta sare leh sida agrichemical, kiimikaad, caag, alaabta cuntada iyo diyaarinta dawooyinka. Saameyntu way ka fiican tahay isku-darka. Kneader waa qalab isku dhafan oo gaar ah oo leh laba dabo. Midka degdega ahi waxa uu badiyaa ku wareegaa xawaare dhan 42 kacdoon daqiiqadii, mid gaabis ah waxa uu ku socdaa xawaare dhan 28 kacdoon daqiiqadii. Xawaaraha kala duwani waxay ka dhigaan walxaha isku-dhafka ah inay si dhakhso ah isu ekaadaan.

Injineerinka Dhirta

- Naqshadaynta dhirta

- Habka la socodka, xakamaynta iyo farsamaynta

- Kobcinta software-ka iyo barnaamijka wakhtiga dhabta ah ee codsiga

- Injineernimada

- Soo saarista mishiinada

Maareynta Mashruuca

- Qorshaynta mashruuca

- Kormeerka iyo maamulka goobta dhismaha

- Rakibaadda iyo tijaabinta qalabka iyo hababka xakamaynta

- Mashiinnada iyo warshadaynta

- Tababarka shaqaalaha

- Taageerada wax soo saarka oo dhan

Qeexida Mashruuca

- Suurtogalnimada iyo daraasadda fikradda

- Xisaabinta Qiimaha iyo Faa'iidada

- Wakhtiga iyo qorshaynta khayraadka

- Xalka Turnkey, hagaajinta dhirta iyo xalalka casriyeynta

Naqshadaynta Mashruuca

- Injineero aqoon leh

- Isticmaalka tignoolajiyada ugu dambeeyay

- Ka faa'iidaysiga aqoonta laga helay boqollaal codsi oo warshad kasta ah

- Ka faa'iidayso khibradda injineerada iyo la-hawlgalayaashayada khibradda leh