Warshadaha Batteryga iyo Walxaha Kiimikada kale Isticmaalka Jidhka Jetka ee sariirta dareeraha leh

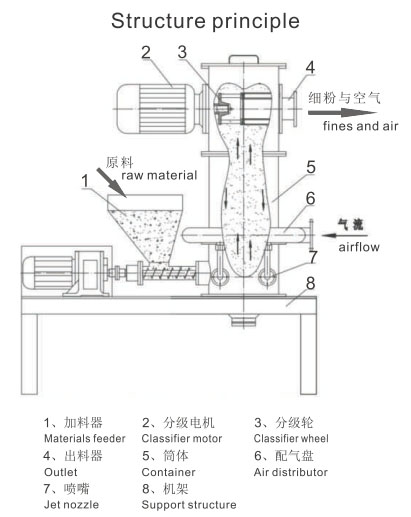

Mashiinnada sariirta dareeraha leh ee sariirta pneumatic-ka ah waa qalabka loo isticmaalo in lagu burburiyo walxaha qalalan ee budada ah, oo leh qaabka aasaasiga ah sida soo socota:

Alaabtu waa dareere sariirta dareere leh oo hawo cadaadisku ay tahay dhexdhexaadiyaha burburinta. Jidhka wax-shiidku wuxuu u qaybsan yahay 3 qaybood, oo kala ah meesha la burburiyo, aagga gudbinta iyo goobta darajada. Aagga Darajooyinka waxaa lagu bixiyaa giraangiraha qiimeynta, xawaarahana waxaa hagaajin kara beddelaha. Qolka wax burburinaya waxa uu ka kooban yahay tuubada burburisa, quudiyaha, iwm. Saxanka sahayda sir sahayda ee ka baxsan qasaacada burburinta waxa uu ku xidhan yahay tuubada burburinta.

Maaddadu waxay ka gashaa qolka burburinta iyada oo loo marayo quudiyaha alaabta. Hawada isku-buufinta ayaa si xawli sare leh ugu shubta qolka burburinta iyadoo si gaar ah u qalabaysan afar nozzles. Maaddadu waxay ku guulaysataa dardargelinta qulqulka jetting ultrasonic waxayna si isdaba joog ah u saameeyaan oo ay isku dhacaan barta dhexe ee qolka burburinta ilaa la jajabiyo. Walaxda la jajabiyey waxay soo gashaa qolka qiimeynta iyadoo kor u kacaysa. Sababtoo ah taayirrada qiimeynta waxay ku wareegaan xawaare sare, marka alaabtu kor u kacdo, qaybuhu waxay hoos yimaadaan xoogga centrifugal ee laga sameeyay rotors grading iyo sidoo kale xoogga centripetal ee laga abuuray viscosity ee socodka hawada. Marka qaybaha ay ku hoos jiraan xoogga centrifugal ka weyn xoogga centripetal, qurubyo aan dhab ahayn ee leh dhexroor ka weyn qaybaha darajo loo baahan yahay ma geli doonaan qolka gudaha ee giraangiraha darajo oo ku soo noqon doona qolka burburinta si ay u burburiyaan. Qaybaha ganaaxa ee u hoggaansama dhexroorka qaybaha darajooyinka loo baahan yahay waxay geli doonaan giraangiraha qiimeynta waxayna ku qulquli doonaan kala-soocida duufaanka ee qolka gudaha ee giraangiraha qiimeynta oo leh socodka hawada waxaana soo aruurin doona aruuriyaha. Hawada la sifeeyay ayaa laga sii daayaa hawada qaadata ka dib daawaynta bacda shaandhada.

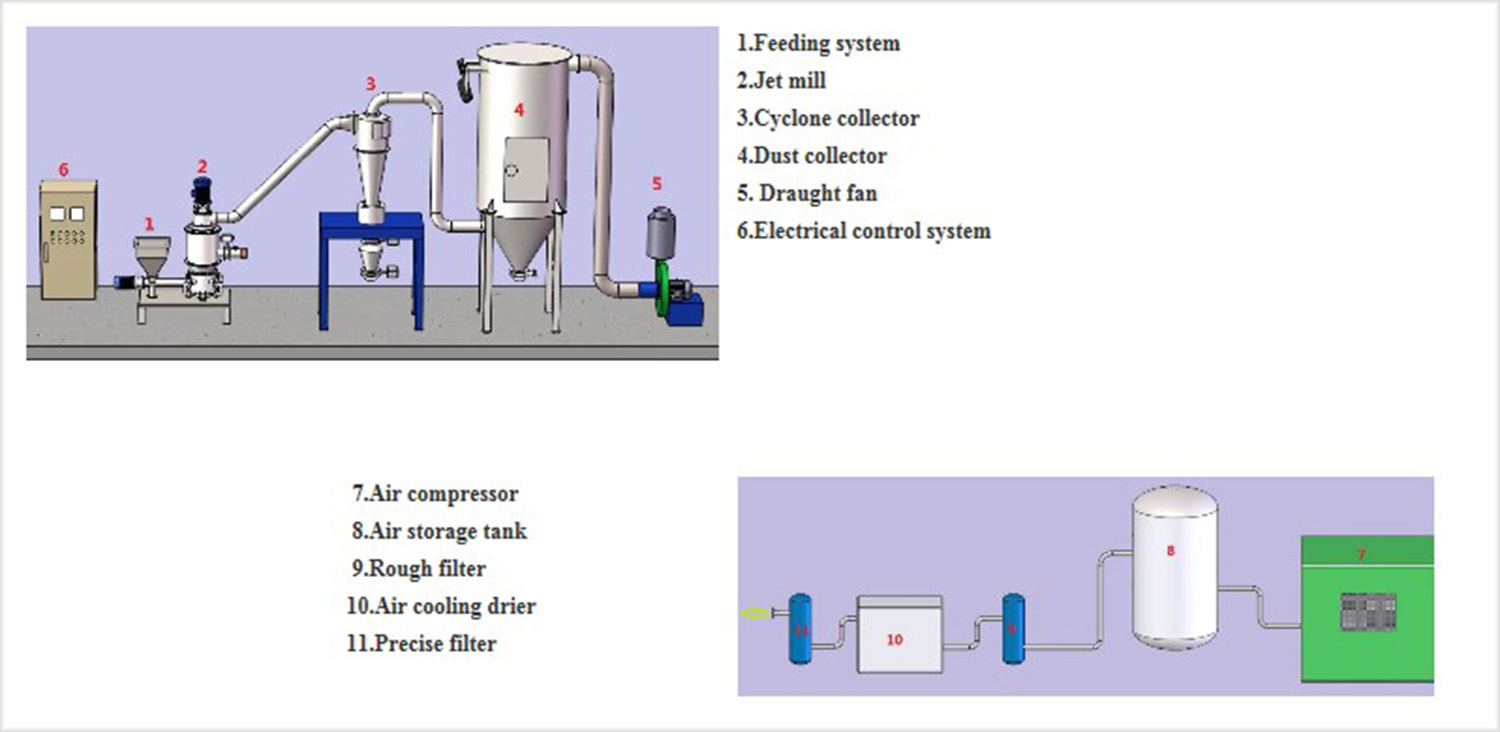

Pneumatic pulverizer wuxuu ka kooban yahay kombaresarada hawada, saliid remorer , haanta gaaska, qaboojiyaha qalajiyaha, filter hawada, dareere sariirta sariirta pneumatic pulverizer, kala soocida duufaan, ururiyaha, hawada qaada iyo kuwa kale.

Bandhig faahfaahsan

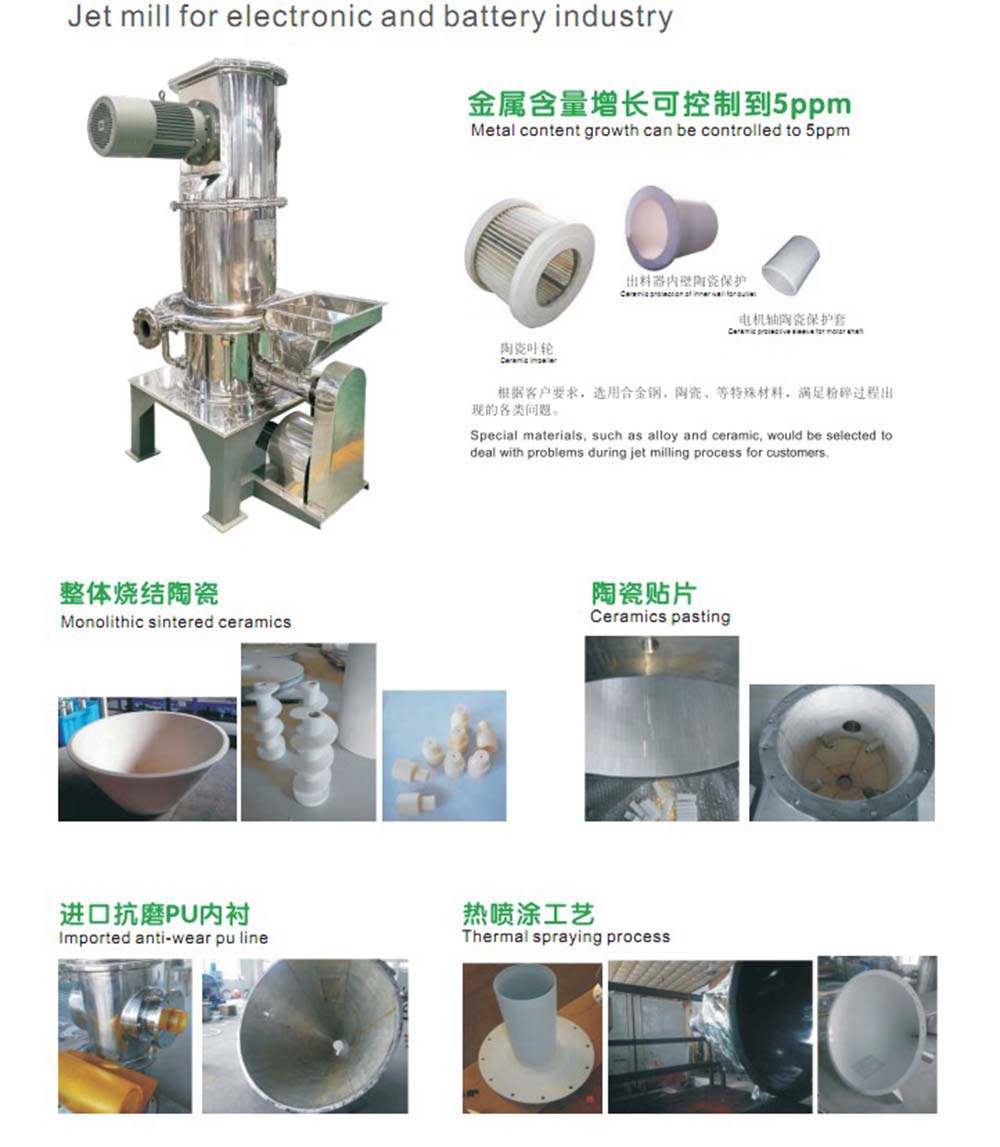

Dheejinta dhoobada iyo dahaarka PU ee qaybaha shiidida oo dhan ee la xidhiidha alaabada si looga fogaado in birta qashinka lagu ururiyo ay horseed u noqoto saamaynta aan ansax ahayn ee badeecadaha.

1.Precision dhoobada dhoobada, 100% waxay tirtiraysaa wasakhowga birta ee habka kala-soocidda alaabta si loo hubiyo nadiifnimada alaabta. Gaar ahaan ku habboon shuruudaha nuxurka birta ee alaabta elektiroonigga ah, sida kobalt acid sare, lithium manganese acid, lithium iron phosphate, Ternary Material, lithium carbonate iyo Acid lithium nickel iyo cobalt iwm baytari cathode alaabta.

2. Kor u kaca heerkulka: Heerkulku ma kordhin doono maadaama alaabta lagu miiray xaaladaha shaqada ee balaadhinta pneumatic iyo heerkulka godka wax lagu shubo ayaa caadi ahaan loo hayaa.

3.Endurance: Waxaa lagu dabaqay agabka Mohs Hardness ee ka hooseeya Fasalka 9. maadaama saamaynta wax-shiidku ay ku lug leedahay oo kaliya saamaynta iyo isku dhaca badarka halkii uu ku dhici lahaa darbiga.

4.Tamar wax ku ool ah: Badbaadinta 30% -40% marka la barbar dhigo kuwa kale ee hawada pneumatic pulverizers.

5.Gaaska daaqsinka ah waxaa loo isticmaali karaa warbaahinta si loo shiido walxaha gubanaya iyo kuwa qarxa.

6. Nidaamka oo dhan waa la jajabiyaa, boodhku wuu hooseeyaa, qaylada ayaa hooseeya, habka wax soo saarku waa nadiif iyo ilaalinta deegaanka.

7. Nidaamku wuxuu qaataa xakamaynta shaashadda taabashada caqliga leh, hawlgal sahlan iyo xakameyn sax ah.

8.Qaab dhismeed is haysta: qolka mashiinka ugu muhiimsan wuxuu ka kooban yahay wareegga xiritaanka si loo burburiyo.

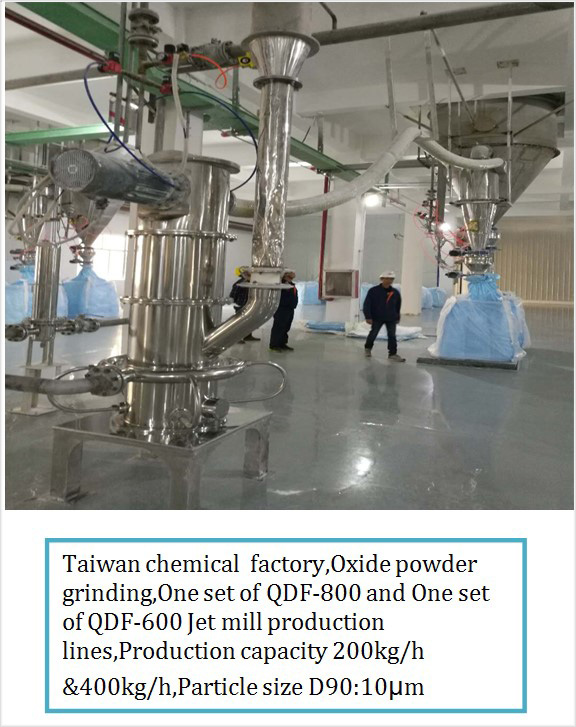

Jaantuska socodka waa habka wax-shiidka caadiga ah, waxaana lagu hagaajin karaa macaamiisha.

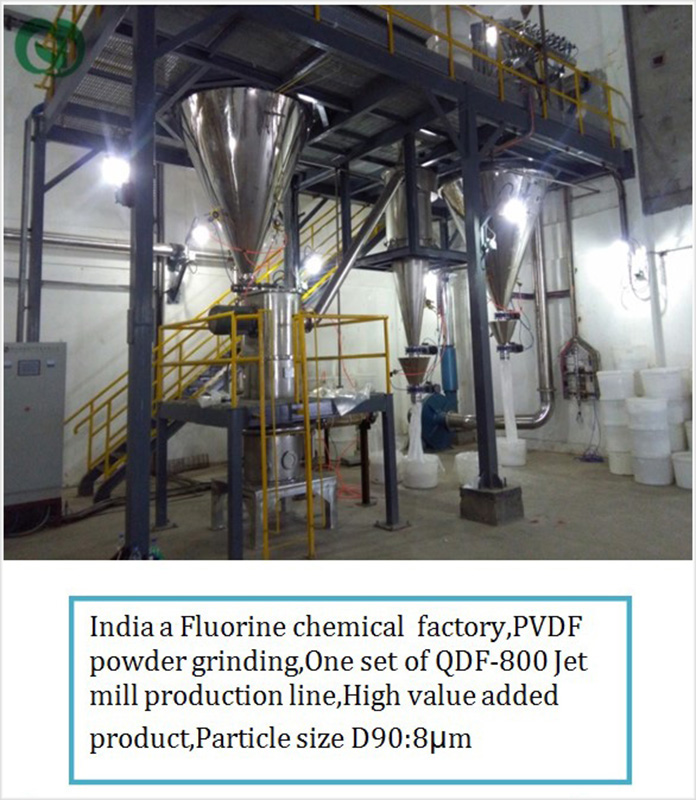

| model | QDF-120 | QDF-200 | QDF-300 | QDF-400 | QDF-600 | QDF-800 |

| Cadaadiska shaqada (Mpa) | 0.75 ~ 0.85 | 0.75 ~ 0.85 | 0.75 ~ 0.85 | 0.75 ~ 0.85 | 0.75 ~ 0.85 | 0.75 ~ 0.85 |

| Isticmaalka hawada (m3/min) | 2 | 3 | 6 | 10 | 20 | 40 |

| Dhexroorka alaabta la quudiyo ( mesh) | 100 ~ 325 | 100 ~ 325 | 100 ~ 325 | 100 ~ 325 | 100 ~ 325 | 100 ~ 325 |

| Wanaajinta burburinta (d97μm) | 0.5-80 | 0.5-80 | 0.5-80 | 0.5-80 | 0.5-80 | 0.5-80 |

| Awoodda (kg/saacaddii) | 0.5-15 | 10 ~ 120 | 50 ~ 260 | 80-450 | 200-600 | 400-1500 |

| Koronto la rakibay (kw) | 20 | 40 | 57 | 88 | 176 | 349 |

| Qalab | Nooca | Dhexroorka qaybaha quudinta | Dhexroorka qaybaha la sii daayay | Wax soo saarka(kg/h) | Isticmaalka hawada (m3/min) |

| Cerium oxide | QDF300 | 400 (Mesh) | d97,4.69μm | 30 | 6 |

| ololka celiye | QDF300 | 400 (Mesh) | d97,8.04μm | 10 | 6 |

| Chromium | QDF300 | 150 (Mesh) | d97,4.50μm | 25 | 6 |

| Phrophyllite | QDF300 | 150 (Mesh) | d97,7.30μm | 80 | 6 |

| lafdhabarta | QDF300 | 300 (Mesh) | d97,4.78μm | 25 | 6 |

| Talcum | QDF400 | 325 (Mesh) | d97,10μm | 180 | 10 |

| Talcum | QDF600 | 325 (Mesh) | d97,10μm | 500 | 20 |

| Talcum | QDF800 | 325 (Mesh) | d97,10μm | 1200 | 40 |

| Talcum | QDF800 | 325 (Mesh) | d97,4.8μm | 260 | 40 |

| Calcium | QDF400 | 325 (Mesh) | d50,2.50μm | 116 | 10 |

| Calcium | QDF600 | 325 (Mesh) | d50,2.50μm | 260 | 20 |

| Magnesium | QDF400 | 325 (Mesh) | d50,2.04μm | 160 | 10 |

| Alumina | QDF400 | 150 (Mesh) | d97,2.07μm | 30 | 10 |

| Awood luul | QDF400 | 300 (Mesh) | d97,6.10μm | 145 | 10 |

| Quartz | QDF400 | 200 (Mesh) | d50,3.19μm | 60 | 10 |

| Bariite | QDF400 | 325 (Mesh) | d50,1.45μm | 180 | 10 |

| Wakiilka xumbo | QDF400 | d50,11.52μm | d50,1.70μm | 61 | 10 |

| Ciid kaolin | QDF600 | 400 (Mesh) | d50,2.02μm | 135 | 20 |

| Lithium | QDF400 | 200 (Mesh) | d50,1.30μm | 60 | 10 |

| Kirara | QDF600 | 400 (Mesh) | d50,3.34μm | 180 | 20 |

| PBDE | QDF400 | 325 (Mesh) | d97,3.50μm | 150 | 10 |

| AGR | QDF400 | 500 (Mesh) | d97,3.65μm | 250 | 10 |

| Garaafka | QDF600 | d50,3.87μm | d50,1.19μm | 700 | 20 |

| Garaafka | QDF600 | d50,3.87μm | d50,1.00μm | 390 | 20 |

| Garaafka | QDF600 | d50,3.87μm | d50,0.79μm | 290 | 20 |

| Garaafka | QDF600 | d50,3.87μm | d50,0.66μm | 90 | 20 |

| Concave-convex | QDF800 | 300 (Mesh) | d97,10μm | 1000 | 40 |

| Silicon madow | QDF800 | 60 (Mesh) | 400 (Mesh) | 1000 | 40 |